Content

We write regular articles that help drivers and businesses become better at all things delivery. Not to mention, Circuit for Teams lets you monitor your team’s routes, make last-minute live changes, and get real-time delivery status updates. And, of course, delivering packages in good condition is how to calculate cost per unit key to maintaining happy customers. Reduce the return rate by making sure your product is high quality, meets customer needs, and is properly packaged and shipped to avoid damage during transit. This means you won’t have to rent or build extra storage facilities, saving you money in the long run.

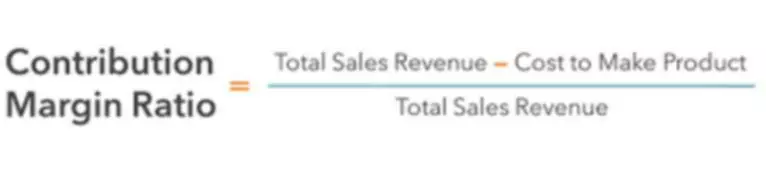

This is why ecommerce companies that sell their own goods must calculate and monitor their cost per unit over time. The product cost per unit is used for valuing a company’s inventory and for determining the cost of goods sold. Fixed costs are spread across all units, thus, for many offerings, the greater the number of units, the lower the average cost.

What is the Cost Per Unit

It generally happens when the production requirements increases and you need to rent more storage units or warehouses. You must recognize that the success of service and product-based businesses dramatically depends on their profit. To know whether your business is a profitable unit, you can check whether your production costs are lower than the cost of each product you are selling. By understanding how to calculate the cost per unit of a product, you can easily set the prices and attain your sales goals. Keep reading to know more about the cost per unit and how to calculate the unit per Price.

- Other costs such as advertising, preparing invoices, delivery expense, office salaries, office rent and utilities, and interest on loans are examples of expenses that are not assigned to the products.

- It is usually simpler to calculate the cost of total production per run or period of time and then divide the amount by the number of units produced.

- It’s also important to properly train your employees to reduce product defects, and only order the necessary direct materials for production.

- In this example, the total cost of production is directly proportional to the output level.

- Some best examples of fixed costs are overhead, salaries, rent, business insurance, property tax, and more.

- If your sales price is $10.00 with total product cost is $7.50 and a 10% discount, your variable costs won’t change much.

- One way to gauge consumer interest is to test your product at farmers markets.

This calculator can also evaluate the total price or number of units given the other variables. If the cost per unit is too high, your business may need to raise the price or reduce expenses to maintain profitability. Factors like the cost of production, demand, competition, and marketing strategies all play a role in determining the price per unit. This means the company must price each unit at more than $21.25 to cover costs and make a profit.

Cost per unit FAQs

These are the total number of prices that the company makes for the specific product. It can affect the variable cost, and so it is an important component of calculating the total cost. The number of units can generally depend on the demand for the product.

- A unit cost is the total expenditure spent to produce an individual unit of goods or services.

- As per the experts, you are improving your supply chain’s efficiency, making it possible to lower storage costs, first-mile delivery, and fulfillment costs.

- A disadvantage of this pricing method is that it might not cover all your costs.

- Another way to look at variable costs is if you were to stop producing any products, then there should be no variable costs on your spreadsheet.

- Variable costs are expenses that can change depending on the production volume or other economic factors.

However, to calculate cost per unit accurately, you will have to understand fixed and variable costs. Investopedia identifies the unit cost as a breakeven point because it is the minimum price at market that will cover production costs. If a good goes to market and sells, any amount above the cost per unit will be considered profit. Depending on the various factors that affect the cost per unit, there are different ways of reducing fixed and variable costs in your ecommerce operations. Below are a few ways to address the issue of a high cost per unit.

Cost Per Unit definition

Unit cost can also be known as the cost of goods sold, average cost, or cost per unit. Businesses use unit costs to see how efficient their product production is. Calculating unit costs is also important in business accounting to organize financial statements and accurately report taxes. Companies can also use unit costs to strategize pricing to produce profits. To calculate the cost per unit, a business needs to use the unit cost formula. Calculating cost per unit isn’t as simple as it seems in manufacturing situations.

Whether you’re a small business or a larger corporation, Circuit for Teams can help you reduce fuel costs and streamline your delivery processes. And by implementing effective customer management practices, you can make sure https://www.bookstime.com/ orders are fulfilled on time and customers are satisfied with their purchases. You can reduce these costs by taking a comprehensive look at your business operations and identifying areas where you can make adjustments.

How to calculate cost per unit

So, to make a profit, the firm should sell the widgets at USD 16.5. If you know what sales volumes to anticipate, you can manage your inventory accordingly to reduce costs. Rather than renting a warehouse and hiring/managing a staff, you can store inventory in multiple fulfillment center locations within our network and track storage costs through the ShipBob dashboard.